NCCM Company, a family-owned business, manufactures high-value and custom-engineered nonwoven rolls for the OEM, metals, automotive, and industrial markets. Our nonwoven rolls are designed to replace traditional roll coverings, like rubber, urethane, other nonwovens, various fabrics, carbide coatings, and have features and properties that no other rolls offer. We offer the original yellow roll made with exclusive and proven 3M materials and proprietary technology. Our goal is to lead the industry in the right direction by providing cutting edge and high value-add products and services that improve NCCM customers’ productivity and product quality while decreasing the cost of production and environmental footprint. We accomplish this through trust, strong relationships, and advanced roll technologies and approach our business calling with a transformative, philanthropic mindset.

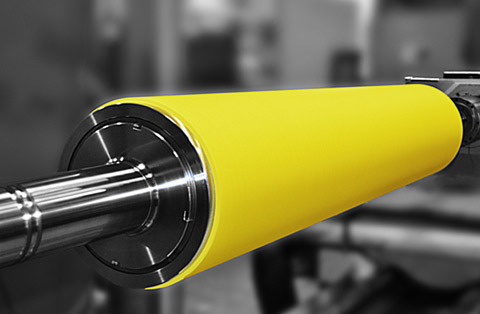

The renowned NCCM® Premier Yellow outperforms any other nonwoven roll in the world and has been a world-class benchmark for 25+ years! With applications such as wringing, oiling, de-oiling, blank washing, and more, the Yellow roll is custom-engineered to succeed in multiple industries and applications. NCCM offers a host of other nonwoven rolls including N2, NS, NT, CX, CX-Plus, and many more. Longer life, superior fluid control, and repairability are just a few of the benefits of NCCM Rolls.

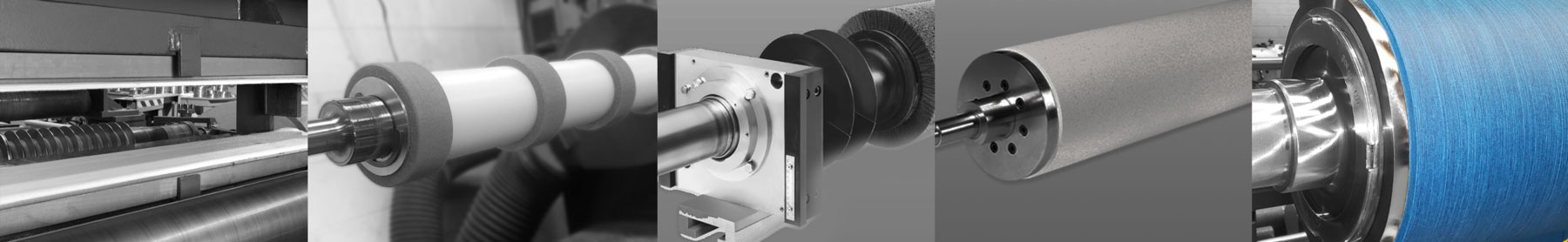

NCCM’s manufacturing and roll service centers in North America , Europe , and Asia are equipped to provide the same unique roll quality standard worldwide and locally. Our lathes and CNC grinders allow us to completely manufacture and recondition everything from small wheels to large rolls to customer specifications. Our scope of supply includes:

• Application-specific nonwoven covers in different cost and performance categories

• Roll and wheel manufacturing, including shafts and accessories

• Reconditioning, recovering, and full service of worn-out roll and wheel covers

We add value to a variety of markets. Select yours below to learn how NCCM rolls can increase your profitability and productivity!

The NCCM value for OEMs and machine builders is the in-depth technical design competence we bring to each new roll based on broad application engineering knowledge.

At NCCM, we focus on surface quality and fluid control functions as well as end-user production process upgrades to deliver significant customer value, including increased line speeds and reduced manufacturing costs.

The unique technical features of the NCCM® Premier Yellow nonwoven rolls provide outstanding benefits for the highest standards in today's automotive blank washing technology.

NCCM nonwoven rolls lead multiple markets, and the same high performance is available for industrial applications. NCCM nonwoven rolls provide a precise solution for previously uneven oil application and result in less oil waste.

Explore some of our recent highlights and check back with us to see what we are up to! We thank you for stopping by.

NCCM will be exhibiting at AIST 2024. Stop by and visit us, we would love to connect and learn more about bringing solutions to your applications.

We wrapped up our 2023 tradeshows with Fabtech in Chicago this year. A great show turnout and opportunity to hear from new and existing customers.

NCCM exhibited at Metec 2023 in Dusseldorf, Germany, June 12-16th. It was great to interact with customers and potential clients, to hear about some of the challenges they face, and show how NCCM products can help provide innovative solutions.

NCCM products and solutions can create tremendous cost savings over traditional rubber and urethane rolls.

Sustainability is much more than environmental impact. NCCM has a global focus on improving our sustainability in multiple ways.

Coming soon.... a complete report about NCCM sustainability

Our 5th annual memorial fundraiser raises funds to honor Lew David Niccum will be held Aug. 11, 2024. Look for more details soon.