NCCM® CX-Series

Chemically-Resistant Nonwoven Rolls

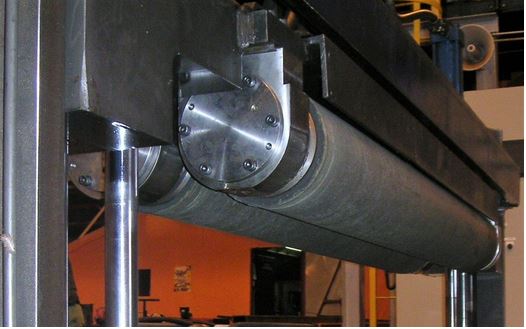

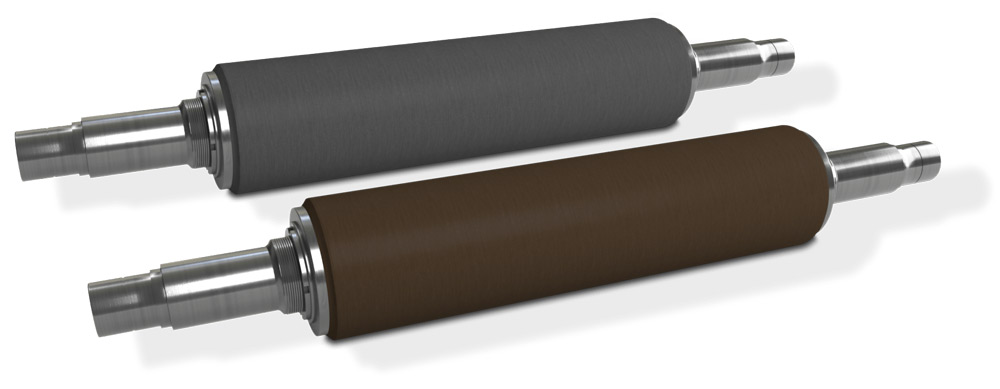

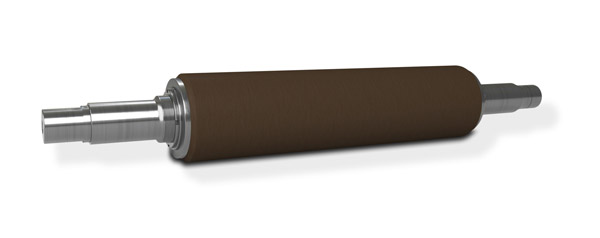

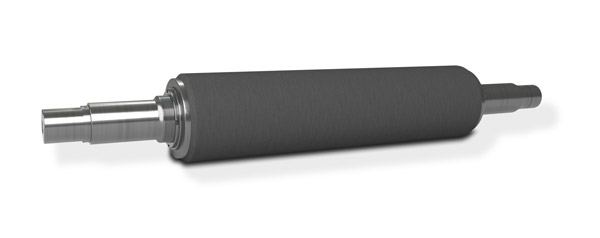

Count on NCCM Company in aggressive environments. Our NCCM® CX-Series mill rolls are the ideal choice for harsh caustic, alkaline and acidic chemistries. They are specially designed to achieve peak performance in caustic cleaners on tinning, galvanizing, or coil coating lines. Self-healing properties provide cut resistance against strip edge damage, and the wear resistance of our high-tech nonwoven material extends roll life long past traditional rubber coverings. Custom-engineered to specification, they can also make a significant contribution to increased productivity and outperform rubber rolls in pickling lines by far. Connect with an NCCM representative to get started and find your VAR (value-added reseller).

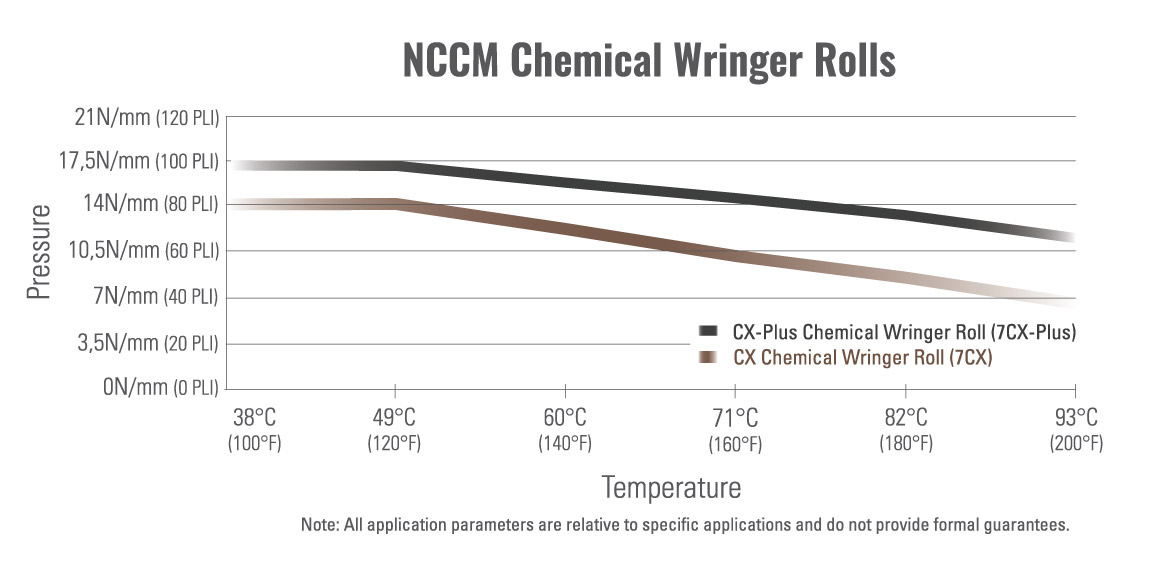

NCCM® CX and CX-Plus chemical wringer rolls operate in a variety of pressure and temperature ranges. NCCM custom engineers each roll for its specific application.

The NCCM® CX-Series has been tested and found to work in all of the listed solutions. To gain more technical information about this product or to check to see if NCCM® CX-Series nonwovens will operate in your specific solution, contact us.

CHEMICALS

1. Sulfuric Acid

2. Hydrochloric Acid

3. Acetyl tributyl Citrate

4. Isopar M

5. Bonderite 1310 1421, 427-RLK

6. Deionized Water

7. Phosphoric Acid

8. PME

9. Norpar

10. Nitric Acid

11. Nickle Flash

12. Chloramine