Outstanding in long life and precision oil film control

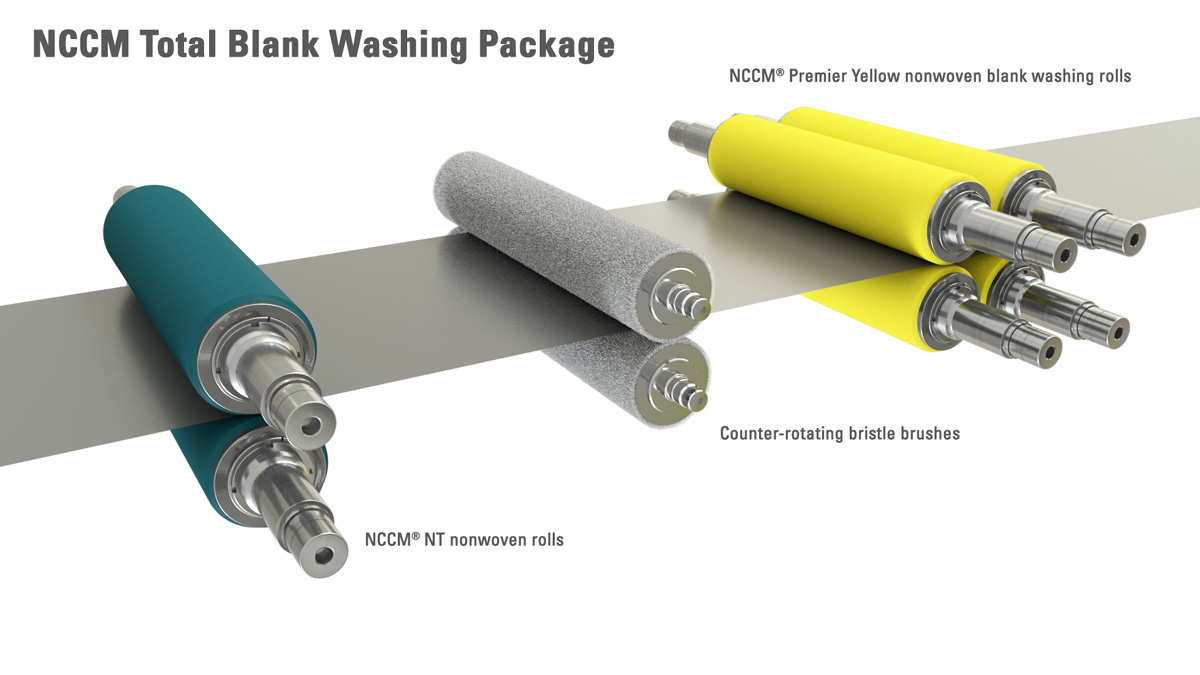

Excellent cleaning and oiling of blanks prevent costly quality errors later on in the stamping process. In a traditional blank washer, nonwoven rolls are no doubt the best option. The type of nonwoven roll in the blank washer makes as much of a difference in quality to the operation as the machine itself. Enter NCCM nonwoven rolls. NCCM’s nonwoven rolls last 2-5 times longer than any other nonwoven. Other products claiming to have long life will cease to perform well as time goes on, but NCCM nonwoven rolls maintain their initial “new roll” performance throughout their whole life (up to 5 regrinds). This consistently superior performance achieves oil film targets to the lowest requirement of below 1 g/m2.

Make the choice to put long life, quality, and consistency first. Make the choice to go with NCCM.

The unique technical features of the NCCM® Premier Yellow nonwoven rolls provide outstanding benefits for the highest standards in today's automotive blank washing technology.

Provides Highly-Engineered Film Thickness

• Maintains film thickness longer

• Reduces hydrostatic stamping defects

• Decreases part rework

• Reduces paint rework

Reduces Fluid Usage

• Reduces welding smoke

• Saves on fluid costs

• Improves part transfer

• Reduces excess fluid on the production line

Provides Longer life

• Best total value system roll

• Higher damage resistance

• Consistent performance