The Soft Touch solution—eliminates scratches and ensures mirror finish surface processing

NCCM® NS delicately handles the most specialized surfaces to reduce material damage and the resulting material waste. If product rejection costs are increasing due to scratches or gouges, NCCM® NS is a worthwhile investment. Connect with an NCCM representative to get started and find your VAR (value-added reseller).

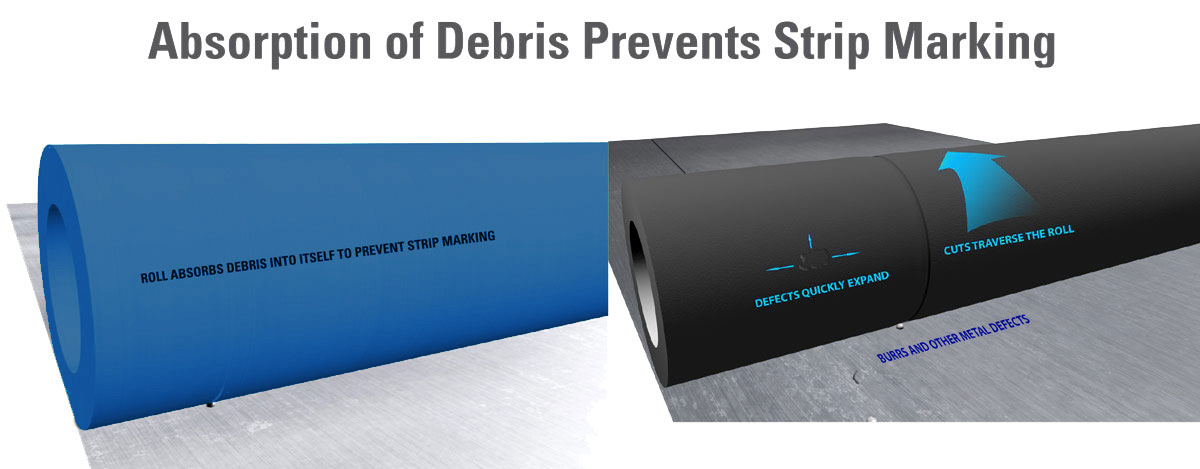

The NCCM® NS nonwoven roll utilizes Soft Touch technology to reduce damage on sensitive metal strips. The roll can pull shards and debris into itself. Most rubber or urethane rolls become marked, trapping the piece of debris against the strip, which damages the length of the strip.