For application-based, quick reviews of NCCM product successes, choose a case study below.

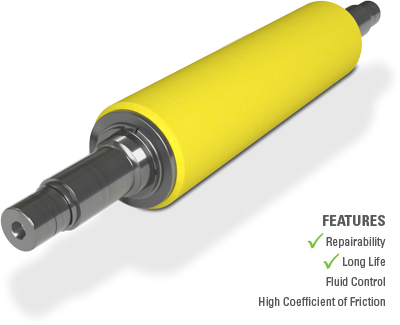

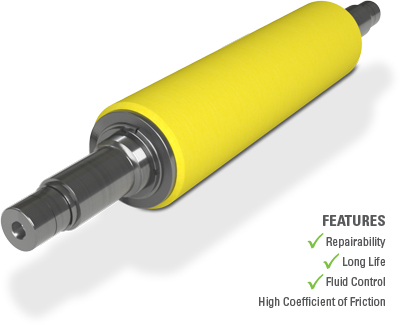

Application: NCCM® Premier Yellow rolls in a reversing application

Initial Challenge: A competitor's nonwoven rolls had to be changed every three months, and the company suspected diameter shrinking due to abrasion was the issue.

Desired State: The company wished to save money and boost production by not replacing their rolls as often.

Custom-Engineered Solution: NCCM ran various tests on the competitor's rolls and discovered the issue to be shape retainability. NCCM nonwoven rolls in the same environment retained their shape due to higher elasticity.

Result and Customer Value-Add: The client put NCCM® Premier Yellow rolls on their line, and the rolls lasted 12x longer than the competitor's rolls with high performance throughout their life.

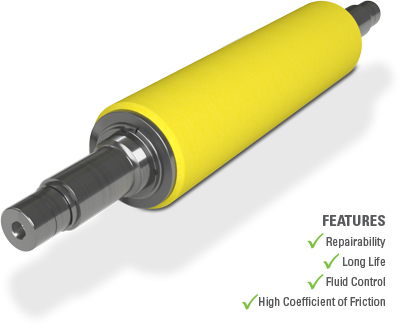

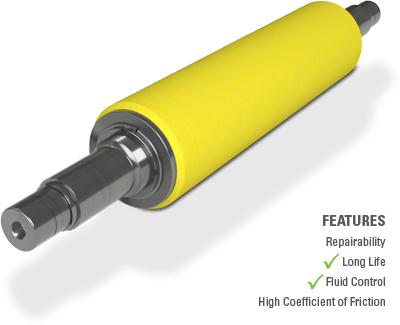

Application: NCCM® Premier Yellow rolls in a reversing application

Initial Challenge: A reversing mill was using a competitor's nonwoven rolls, but the rolls were not lasting between maintenance cycles. Some of the rolls only lasted a matter of hours before failing.

Desired State: The reversing mill was looking to get more service life from their rolls to save on shipping, inventory and excess line downtime costs.

Custom-Engineered Solution: NCCM representatives visited the plant and collaborated with an NCCM VAR to understand the issue. NCCM rolls were installed within a few weeks.

Result and Customer Value-Add: The NCCM® Premier Yellow rolls lasted the full maintenance cycle, and when the line was shut down for maintenance unrelated to the rolls, NCCM reground their rolls to provide even more service life.

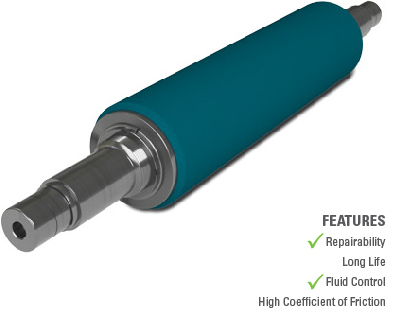

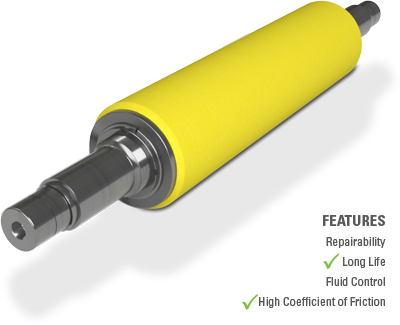

Application: NCCM® NT vacuum roll (VT density) in a rinse section of a push/pull pickle line

Initial Challenge: A customer was experiencing excess fluid pass-through and edge wetness issues from the rinse section on a push/pull pickile line.

Desired State: The customer wanted to address and solve the edge wetness issue.

Custom-Engineered Solution: NCCM and one of its VARs addressed the situation through better nonwoven sleeve design, improved shaft design and a specially-engineered NCCM® VT density vacuum roll.

Result and Customer Value-Add: The holistic solution improved fluid control and wringing uniformity. The company ordered several more rolls and expanded NCCM vacuum roll use to additional locations.

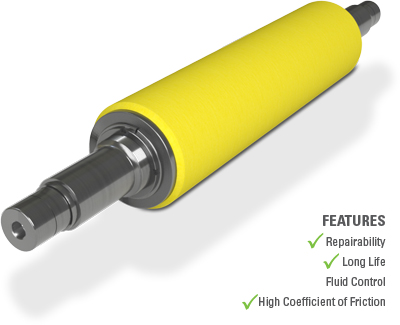

Application: NCCM® Premier Yellow in a hold down flattening application

Executive Summary: An NCCM® Premier Yellow nonwoven roll lasted 13 times longer than a urethane roller due to the NCCM feature of repairability, which allowed the roll to be reground.

Application: NCCM® Premier Yellow in a blank washer

Executive Summary: An NCCM® Premier Yellow nonwoven roll provided oil film thickness control 7 times longer than a competing nonwoven roll in a blank washer.

Application: NCCM® Premier Yellow in a cleaning application

Executive Summary: An NCCM® Premier Yellow nonwoven roll replaced urethane rolls in a cleaning section on a coil processing line and decreased staining and roll change frequency.

Application: NCCM® N2 as a cyclical pinch roll

Executive Summary: The customer was looking for a cost-effective and high-performance solution for their cyclical pinch roll that would retain its precise shape and continue to have a high coefficient of friction to reduce slippage. NCCM® N2 was installed and matched all requirements right to the point.

Application: NCCM® Premier Yellow as skate wheel hold-down rolls

Executive Summary: NCCM® Premier Yellow being used in a small skate wheel application can be utilized in a variety of value-add applications, including a trial for welded blanks. The customer machine builder used the application design to hold down blanks during the welding process and in a bar straightening and grinding equipment.